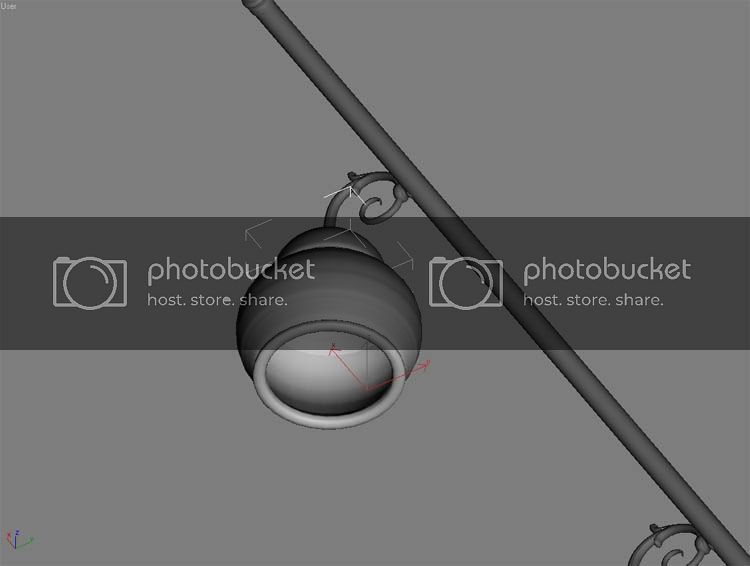

So I think they are actually more complicated that the example that I showed to you before. Out of curiosity, just as many modeling software estimate a complex surface as a mesh of planes or triangles, could the same principle be used for the lighting fixtures themselves. In other words, instead of seeing each fixture as a single complex surface, can it be considered it as just a group of flat planes? One item that I need to have addressed is whether I should model the diffuse shades a single surface or if it acceptable to have inner and outer surfaces (you can think of it as having a thickness to it). See here:

http://i35.photobucket.com/albums/d178/marcdevon/luminaireview.jpg

Hi Marcus,

Without actual photometric data (such as an ies file) to apply to your group of flat planes, you have to model the actual comple geometry. But I'm afraid I may have misunderstood your question. As for the single/dual surface question, I guess it depends on how close your views will bring you to the shade. The trans material is infinitely thin, and it'd be best to model the thng as a single surface. For closeup work, you may need to introduce thickness but that's gonna get a lot more complicated from a valid material definition standpoint.

The information in Rayfront's user manual and pages 325-326 from RwR were VERY useful to me in gaining insight as to how Radiance treats light. There was a word that was mentioned that has me worried. Measure. Aside from not having any experience with performing a empirical test of light distribution, measuring light sounds very expensive. May I ask, would purchasing the needed equipment require a second mortgage to be taken out or giving up one's first born? Is it required to use transfunc or transdata in lieu of trans to obtain acceptable accuracy?

Mmmm, measurements, yeah. The gear can be expensive. Let's see, at my old job, where I did these measurements, I used an illuminance meter, a luminance meter and a theatrical spotlight (ETC Source Four HID, aka "leko", or ERS). The light fixture was a free sample, but you could use other sources too. The illuminance meter (Minolta Somethingorother-nowdiscontinued) was about $800 and the luminance meter (Minolta LS-100) was more expensive, I believe almost three thousand USD. Actually, here are a couple of links I just found for the meters I used (the illuminance meter I link to here is a newer model than I used, but it's basically the same thing).

http://www.tequipment.net/MinoltaTL1.asp

http://www.tequipment.net/MinoltaLS100.asp

It's expensive not to mention time-consuming, but it's also fun and is an excellent example of the power of Radiance, in that Radiance is happy to accept material data as complex as you are willing to gather.

Maybe Peter can chime in with his thoughts on this stuff, and maybe an update on his goniophotometer project?

- Rob

···

On Jun 3, 2006, at 8:30 AM, Marcus Jacobs wrote: